Build-Test (BT) Domain

Tomohisa HASUNUMA

Director and Professor

Engineering Biology Research Center, Kobe University

Tomohisa HASUNUMA

Director and Professor

Engineering Biology Research Center, Kobe University

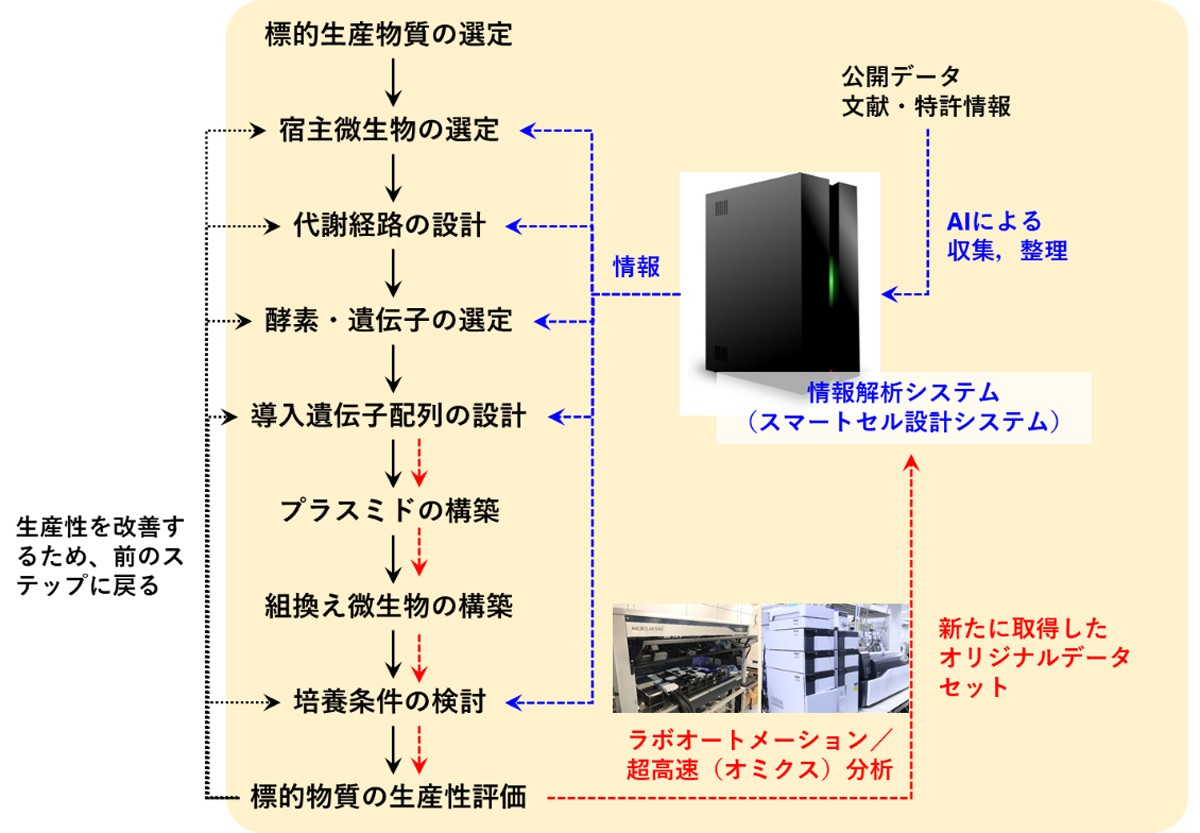

In basic technologies for the Build and Test steps of the DBTL cycle, automation technology has made remarkable progress in recent years. In conventional microbial breeding, after DNA to be introduced into microorganisms is designed and constructing the designed DNA, the processes of plasmid construction, transformation (genetic recombination), examination of culture conditions, and productivity evaluation are performed manually. Currently, on the other hand, robots have been developed that semi-automatically perform the processes from plasmid construction to simple productivity evaluation.

In general, in microbial breeding using genetic recombination, it is necessary to enhance or reduce the expression level of a specific gene to a specific level at a specific time. To achieve this, it is necessary to have at hand molecules involved in the gene expression regulation as available parts. These parts include promoters, repressors, RBS, and terminators, and are collectively called "DNA parts." In the current molecular biological knowledge, DNA parts are not clearly specified, and the expression level of genes varies depending on their combinations. Therefore, trial and error through experiments is required. Under these circumstances, business ventures in the United States and other countries have already created a lab automation system that automatically performs bio-operations using catalogued DNA parts and robotics.

In the NEDO Smartcell Project, we have been developing our original high-throughput technologies, such as high-throughput long-chain DNA synthesis technology with the highest DNA integration accuracy in the world, a technology for constructing diverse microorganisms in a short time using long-chain DNA, and a technology for obtaining productivity data and omics data with high accuracy and high throughput. In particular, we are working on the following research and development themes.

1. Development of a long-chain DNA synthesis and analysis technology

2. Development of a high-throughput microbial construction and evaluation technology

3. Construction of a platform for searching for compound efflux transporters

4. Development of metabolite sensors

5. Development of an autofluorescence microscope

6. Development of a transcriptome analysis technology

7. Development of a technology for high-accuracy, quantitative, targeted proteomic analysis

8. Development of a metabolomic analysis technology

9. Networking of the evaluation system

Long-chain DNA is extremely useful for high-speed breeding of microorganisms because it can enhance and reduce the expression levels of many genes by one recombination operation. It also leads to the realization of new metabolic pathways designed by information analysis in a short period of time. The main achievements so far are as follows.

●Establishment of a technology to synthesize long-chain DNA of more than 30 kb in size accurately (mutation rate 0.1% or less) at a low cost (5 yen per base) in a period one-quarter that conventionally taken (about 2 weeks).

●Establishment of a semi-automatic high-throughput transformation technology using a 96-well plate format

●Development of a platform for searching for compound efflux transporters

●Development of a technology for high-throughput evaluation of the target material productivity by image analysis, etc.

●Development of a microbial proteomic analysis technology capable of quantitating proteins

●Construction of a high-throughput, high-accuracy, comprehensive metabolomic analysis system through the development of preprocessing robots, etc.

In this project, we are working on the incorporation of basic technologies into the Platforms Creating Smart Cells (Fig. 1). In addition, we are systematically obtaining and managing data by further improving the accuracy of our original high-throughput evaluation technology and strengthening the coordination with information analysis technology.

図1.スマートセル創出プラットフォームを利用したワークフローの例

Many of the useful materials required for bioproduction are biosynthesized in cells from common precursors. These precursors are defined as "hub compounds," and strains with a high productivity to produce the hub compounds are defined as "chassis strains." Once a chassis strain is generated, it becomes possible to shorten the breeding period of the target production strain, using the chassis strain as a host. Therefore, chassis strains have high industrial demand.

Conventionally, an enormous amount of time has been required to isolate and breed useful hosts. However, through this project, the development period of chassis strains and practical strains can be shortened, by utilizing a highly efficient multiple gene transfer and destruction technology using long-chain DNA, a technology for optimizing expression levels of multiple genes, semi-automatic high-throughput transformation technology, and a high-throughput evaluation technology.

We are verifying the effectiveness of the Platforms Creating Smart Cells, using specific production materials targeted by private companies, by expanding the scope of its application not only to general-purpose microorganisms, such as Saccharomyces cerevisiae and Escherichia coli, but also to industrial microorganisms.

Last updated:December 25, 2023